THE PHYSICS OF SADDLE MAKING

SADDLE PHYSICS & FITTING

QUESTIONS? GIVE US A CALL AT 706-886-0314

Not

ALL SADDLES

fit

ALL HORSES

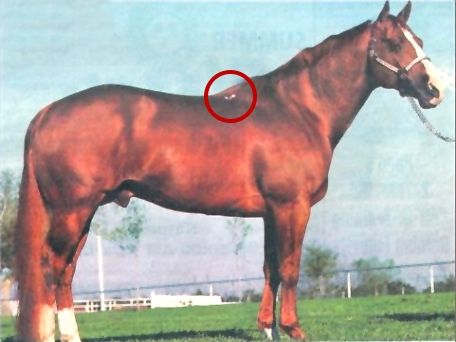

The picture to the left shows a white spot in the middle of this horse’s back. While most saddles have too flat of bars, which will bridge on most horses, this picture is indicative of a bar with too much curve. While great for low-backed Thoroughbred animals, it will not work for flatter backs like those above that normally are found on horses with cutting blood. Those white spots tell you that the saddle is putting too much pressure on the spine

Thirty years ago, while working for a great saddle engineer, I had a personal epiphany. While designing a new cutting saddle, a new tree bar came into being and in a modified version has stayed with this company its entire existence. It has made Caldwell Saddles fit and ride better than most others available on the market today. And it all starts with conformation of the horse. A horse's back has a slight curve upward from behind the withers to the point of loin. The lowest spot, called the "sweet spot" (Fig. #1), is where you are the most balanced and most comfortable. This is where the animal would wish that you ride for his comfort also.

"I KNOW the riders can help them more by the saddles they ride now. RIGHT?!? I applaud the lifetime achievements that you and Tom have contributed to the sport!!! Love ya!" Joan

Saddles (unfortunately) traditionally have had trees that placed the rider against the cantle (Fig. #2) instead of in the center of the equine back (Fig. #3).

Our saddles are most often, but not exclusively, used for horses ridden frequently and for performance events. The purpose of riding by anyone is for one of the two P's - Pleasure or Profit. An uncomfortable ride is not fun, and a bad fit is not going to win you any money. The horse will quit or not be able to perform to his ability.

Here we need to address "treeless," rubber bars, and bareback. The true back area (occupying the area behind the withers and in front of the loin) is only about 14" long. This is not a strong area, if it were, we would not need saddle bars to spread out the rider's weight. TEST - Place your hands on this area (Fig. #1) of the unsaddled horse and push down and release repeatedly. The horse's back will bounce with your hands. Pressure centered on this area alone for an extended period of time is uncomfortable to the horse and can cause injury. For these reasons, "treeless", rubber bars, and bareback are not recommended.

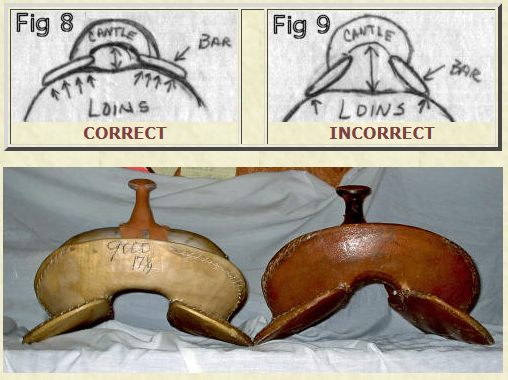

Correctly formed trees will have "spread", "twist", and "flare." Standing behind the horse looking towards his head (Fig. #8 and Fig. #9), you can see by the "spread" how the bars fit into his back instead of on his back.

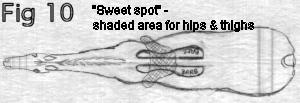

Next, look down from above the animal (Fig. #10), one can see that where the sweet spot is located the back naturally narrows and should do so in the tree also. This is called "twist", giving you a comfortable place to sit. Then the front of the bars should "flare" out to sit on (not behind) the horse's shoulders.

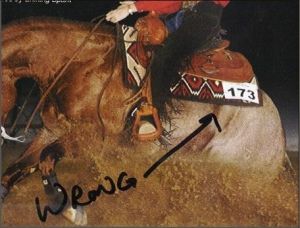

The saddle is sitting behind his shoulders and not onthem. No saddle shoulder ever rest w/ the front end of the saddle in the soft tissue behind the shoulders.

"I KNOW the riders can help them more by the saddles they ride now. RIGHT?!? I applaud the lifetime achievements that you and Tom have contributed to the sport!!! Love ya!" Joan

There are 3 reasons that a saddle is behind the shoulders:

- Saddle is the wrong shape for horse, too narrow of saddle will go back behind shoulders when he steps forward because shoulder blade will push it back

- Rigging is too far forward to allow saddle to be pulled up to the shoulders

- You put it there

Please refer to caldwellsaddle.com. Go to SIDEBARS; barrel horse fit, physics, saddle fit video. After you look at these you will have a much better understanding and knowledge to fit and keep your horse well and happy.

Please refer to caldwellsaddle.com. Go to SIDEBARS; barrel horse fit, physics, saddle fit video. After you look at these you will have a much better understanding and knowledge to fit and keep your horse well and happy.

We have discussed the shape of the Caldwell tree, lets look at others keeping in mind that these trees are found in saddles ranging in price from $500 to $5,000. DO NOT THINK THAT MORE MONEY FOR A SADDLE WILL NECESSARILY SOLVE YOUR FIT PROBLEMS. There is an often-used term to describe tree width that is particularly misleading: "full" or "semi-quarter horse." This is like saying that every person wears an athletic shoe (generally called tennis shoes) with no arch support and is either a size 5 or size 10. Note in Figure #9 how the tree is above the animal by several inches raising the rider to an unstable position and pressing down with just the sharp outer edges of the tree. These trees have upright bars all the way across the back to the withers - there is no spread, no twist, no flare. To get a "full quarter horse bar" (Fig. #11), these bars are simply pushed apart further for a fuller horse. For the narrow framed horse, the bars are moved closer together on the "semi-quarter horse bar" (Fig. #12) before adding the swell (front) and cantle (back).

These procedures do improve the carrying position of the saddle for the horse, but widens the middle to give the rider a most unpleasant wide ride due to this area pressing on the inside of the rider's thighs and narrowing the bars causes "bridging" (see below). This also places the rider on the horse's loins instead of the center of his back.

If you have a frequently ridden horse that you would like to evaluate, try standing beside him unsaddled, run your thumb and forefinger down the center of his back from the withers to the hips, pressing firmly. He should not give to this pressure. If he bows his back trying to get away from the pressure, he is probably sore from an ill-fitting saddle.

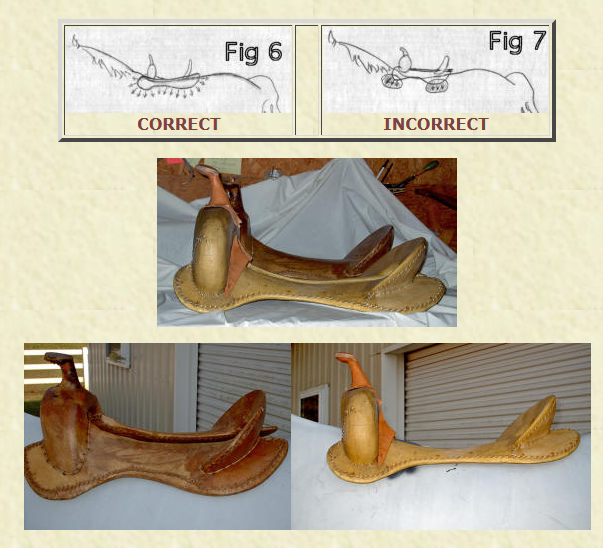

Saddle trees are directly responsible for the shape of the saddle seat. A saddle that sits to the rear has a tree that "bridges" a horses back and does not fit properly "into" his back. Figure #6 is applying pressure evenly to all parts of the shoulder, back, and loin. A saddle should span all of these areas to spread the rider's saddle weight evenly thus reducing the pounds per inch.

Please note: When the saddle is behind the shoulders the balance is off. Pressure on the soft tissue behind the shoulders can damage nerves from the brain to the front legs. It can cause white pressure spots and dips in the tissue.

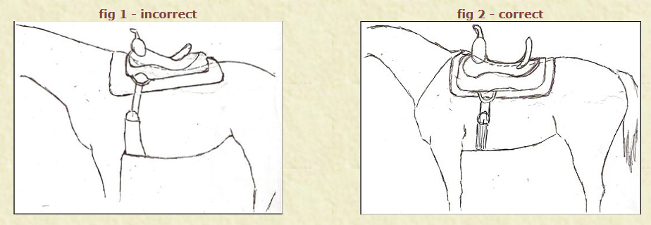

It can be really simple to see if your saddle and pad fit your horse and are in the right place. After saddling, step back and look to see if the bottom edge of the pad and saddle are parallel to the ground. If not (as in fig 1) move the pair forward up on the shoulder till the bottom edge is level with the ground (as in fig 2). If it will not stay there; your saddle is too narrow. And please be aware that you CANNOT use a flat backed or low contoured pad on a high withered or extremely low backed horse. It will pull your

saddle back.

THE PHYSICS OF SADDLE MAKING

A discussion of why traditional saddle design needs to be rethought.

When asked about sores and white hairs on a horse’s back, Charon replied, “People have often told me, ‘my horse has white spots on his withers.’ This is not an entirely accurate description. The spots actually form behind and/or to the side of the shoulder, near the withers. Incorrect saddle placement is the only thing that causes these white spots, but there can be several reasons for why the saddle is not in the correct position on the horse’s back:

1) Saddle is too narrow to stay up on the shoulder even if the saddle was originally placed there.

2) Front rigging is too far forward so the saddle cannot be placed far enough up on the shoulder and still have the cinch behind the front legs.

3) Straighter shoulders, common in today’s faster horses, lead people to believe the saddle ‘looks’ wrong in the correct place.

Note: To properly check placement, after cinching your saddle, try placing your hand under the saddle at the shoulder and at the rear where the bar of the saddle rests. If you can get your arm all the way under the rear and cannot work your fingers under the front, your saddle is too far back – for any of the above reasons."

So a well-made tree will help keep the back of a horse healthy. “Correctly formed trees will have spread, twist, and flare,” reiterates Charon. “Standing behind the horse looking toward the head, you can see by the spread how the bars fit into the back with the competitors tree instead of on the back with our tree. Next look down from above the horse and you can see where the ‘sweet spot’ (the area you should actually be sitting) is located. It is where the back naturally narrows and this is where the tree should also narrow. This is where ‘twist’ comes into play and it gives you a comfortable place to sit. Then the bars should ‘flare’ out to sit on, not behind, the horses’ shoulders to allow him proper movement and flexion.”

PERFORMANCE RACER

For years our equine industry has produced saddles for professionals and serious non-pros that, although being a little more expensive due to better tree and materials, would last a competitor twenty or thirty years with normal maintenance. That is in all events but barrel racing. Due to the use of in-skirt rigging, while giving a great ride because of its flat profile under the rider’s leg, these saddles have worn out much faster. This is because the purpose of a skirt is not only to balance a saddle across the horse’s back, but to absorb and keep sweat away from the front rigging, which is what ties the saddle onto the animal.

A saddle with the rigging “hung” over the skirt and mounted by nails, screws, and sewing to the tree is stronger and much more durable than in-skirt rigging. A hung rigging is also much cheaper to repair should there be damage or an accident because regardless of what we better saddle makers use, it’s still leather, not steel.

There are other disciplines that have a limited availability of in-skirt rigged saddles. These, however, are accepted as a less expensive version. But with barrel racing, there has never been much option out there.

We at Caldwell Saddle are offering a “Performance Racer”, Front Rigged off the tree with the same look of a pocketed “Mother Hubbard” style rear skirt. For strength and durability we recommend a leather covered horn or exposed white bronze horn, and the use of latigo tie strap and harness leather off billet or latigo half-breed strap.

This saddle will last as long as any contemporary hard used saddle such as a cutting or roping style saddle. The initial price is less than 10% increase, yet this is easily compensated by not only longer and harder usage, but increased resale value.

While we are discussing rigging, note the following two pictures.

The purpose of a FULL RIGGING POSITION is to fit a full 45 degree angle shoulder and still fit on the shoulder. Unfortunately there are hardly any horses left of that angle, because breeding for speed in all of our event horses; i.e. roping, barrel horses, cutting horses nowadays are straighter shouldered. Horses like that need a rigging set back to allow the saddle to move forward onto the shoulders. We even allow less on trade-in values for the full-rigged saddles because they are so limited by what they will fit.

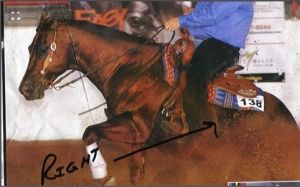

Reining Horses: Photos #1 and #3.

Why worry about saddle placement and fit for these extraordinary athletes? Poor fit is costly. When the saddle is in the soft tissue dip behind his shoulders instead of on the solid bone of the shoulder scapula, the point of the tree bar digs into him like a fingernail behind YOUR shoulder blade. He will stop turning and spinning because he will not want to turn into the pressure because in training they are taught to move away from pressure. (Note cutter in picture #2).

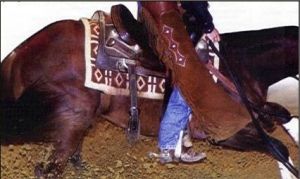

Look at how high the back of this ill-fitting saddle is raising up off of the horse's back!

If you notice, the rider is sitting in the back of the saddle, not themiddle. This is caused by two things;

1. Firstly, the saddle is too far back which places the rider 4" behind the middle of the horse's back. This is caused by the front rigging being too far forward, so the rider cannot move the saddle up.

2. Next the ground seat and the tree are not correct. The low spot in the saddle is in the back of the cantle and not the middle, so the only place the rider can sit is against the cantle. When you sit behind the horses' mid-point, you are going to get a rough ride and you are going to impede the horse's gait and balance.

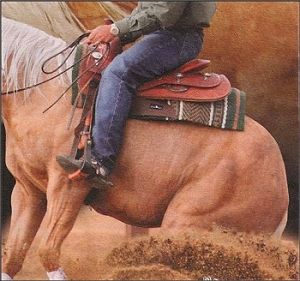

Photos below show another example of ill fit: This saddle while placed on the shoulders as it should be shows a rare instance of a tree too wide for the animal so in a stop, all the rider's weight is thrown on the shoulders instead of balance across his back. How many times will he continue to stop if it hurts him? I know that we all wish that we could buy one saddle to fit our young horses and our aged campaigners but it just isn't going to happen.

Example of White Hairs

Above is one of the most important and greatest cutting horse stallions of all times. He was ridden by undoubtedly one of the greatest riders, cutters, cowmen, and trainers ever. The reason why he has these white spots (they are on both sides) is even he did not know how to fit a saddle onto this horse. Do not think your friends or trainers can always help you get it right with your horse.

When asked about sores and white hairs on a horse’s back, Charon replied, “People have often told me, ‘my horse has white spots on his withers.’ This is not an entirely accurate description. The spots actually form behind and/or to the side of the shoulder, near the withers. Incorrect saddle placement is the only thing that causes these white spots, but there can be several reasons for why the saddle is not in the correct position on the horse’s back:

1) Saddle is too narrow to stay up on the shoulder even if the saddle was originally placed there.

2) Front rigging is too far forward so the saddle cannot be placed far enough up on the shoulder and still have the cinch behind the front legs.

3) Straighter shoulders, common in today’s faster horses, lead people to believe the saddle ‘looks’ wrong in the correct place.

Note: To properly check placement, after cinching your saddle, try placing your hand under the saddle at the shoulder and at the rear where the bar of the saddle rests. If you can get your arm all the way under the rear and cannot work your fingers under the front, your saddle is too far back – for any of the above reasons."

So a well-made tree will help keep the back of a horse healthy. “Correctly formed trees will have spread, twist, and flare,” reiterates Charon. “Standing behind the horse looking toward the head, you can see by the spread how the bars fit into the back with the competitors tree instead of on the back with our tree. Next look down from above the horse and you can see where the ‘sweet spot’ (the area you should actually be sitting) is located. It is where the back naturally narrows and this is where the tree should also narrow. This is where ‘twist’ comes into play and it gives you a comfortable place to sit. Then the bars should ‘flare’ out to sit on, not behind, the horses’ shoulders to allow him proper movement and flexion.”

Please note differences in types of horse.

The drawing below shows how to find the angle of the slope of the shoulder.

For a better understanding, watch the Saddle Fit DVD.

HIGH PERFORMANCE SADDLES are what we do . . . and we do them very well indeed. Consider the comments above.

Why do these people -- and many others -- speak so highly of our saddles? There could be any number of reasons, but they all revolve around the same aspects: quality in design and in execution.

There are many saddlemakers; they can be divided into two broad categories - those who make production line assembly saddles and those who build custom, hand-made saddles. Custom saddles follow traditional building techniques. They are made from the best material available, using no shortcuts, and built by highly skilled workers. In the making of production saddles, costs are cut by using an assembly line, cheaper materials, and techniques that shorten labor time.

Assembly line builders frequently build on speculation and in bulk. In order to reduce material costs they tend to use:

• Fiberglass or plastic trees

• Argentine or imported leather

• Cotton stitching

• Machine pressed tooling

• Nickel plated hardware

• Plastic stirrups and a Traditional design.

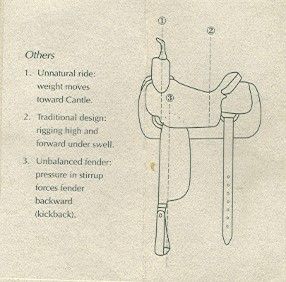

The diagram shows some of the problems with traditional design. The rigging (1) is placed high and forward under the swell and the rearward seat (2) shifts the rider's weight toward the cantle, resulting in an unbalanced rider. The fender also is unbalanced; stirrup pressure forces the fender backwards (3). The net result is that both horse and rider are out of balance and synchronization.

Caldwell Saddle Company is a custom builder, since our saddles are cut, fit, and finished one at a time. We see no need to cut material costs, since we wish to give each customer our very best work. With each of our saddles we will use:

• Our own custom-built wood trees (hand-sewn rawhide over southern yellow pine)

• American leather from Hermann Oak

• Hand-sewn 5-strand nylon stitching

• Hand tooling

• All stainless steel hardware and

• Metal-bound wood stirrups.

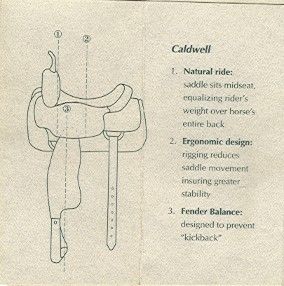

Our design gives a mid-saddle seat (2) which equalizes the rider's weight over the horse's entire back. The rigging design (1) ensures greater stability (and comfort to both horse and rider) by reducing saddle movement. These two factors, along with a difference in fender design (3), reduce or prevent the "kickback" found with traditional saddles.

There are plenty of custom saddle makers, but our unique designs, as discussed above, place Caldwell Saddle at the pinnacle of tailor-made performance saddles.

NOTE: Also see the Physics of Saddlemaking.